Pressworked Products (Stamping)

Published: 11th April 2016

Ford Component Manufacturing has used Pressworking or Stamping as a method of cold forming sheet metal into various shapes, for over a hundred years.

Sheet metal forming is widely used by Ford Component Manufacturing to produce industrial pressed parts used in many industrial sectors – from aircraft parts to a tin cans in the food industry

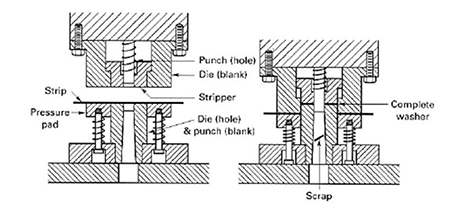

When pressing metal the machine tool punches the workpiece with great force. The forming tool is placed in the press machine’s upper part and when it hits the sheet metal, the required piece is formed or part formed depending on the parts complexity. The lower part of the press machine contains a form tool corresponding to the upper piece. After the pressing machine has performed its cycle and the upper part of the tool is lifted the press is ready for another workpiece. Many or our machine presses can do several hundred cycles per minute. When the pressing is done, the workpiece is the same shape as the tool. Of course, this means that every component needs a customized tool and a corresponding tool for the press machine’s lower part, sometimes referred to as a die.

When pressing metal the machine tool punches the workpiece with great force. The forming tool is placed in the press machine’s upper part and when it hits the sheet metal, the required piece is formed or part formed depending on the parts complexity. The lower part of the press machine contains a form tool corresponding to the upper piece. After the pressing machine has performed its cycle and the upper part of the tool is lifted the press is ready for another workpiece. Many or our machine presses can do several hundred cycles per minute. When the pressing is done, the workpiece is the same shape as the tool. Of course, this means that every component needs a customized tool and a corresponding tool for the press machine’s lower part, sometimes referred to as a die.

Some of this tooling does not need to cost the earth! Ford Component Manufacturing offer a Low Cost Tooling (LCT) option, typically, the tool costs are 90% less than a conventional press tool and takes significantly less time for the tool to be manufactured. This provides the customer both lead time benefits for the first batches as well as significant cost benefits against standard production methods

Which of our press machines are most suitable for which component is determined by the workpiece’s length and width (X,Y), the press force (measure in tons or kN) and material specification.

The press force is usually the most critical aspect of the metalworking process. This is the force the upper part of the machine tool has when it hits and presses the metal workpiece. We determine what this force needs to be by the type, thickness and the amount of material to be pressed. Big sheet metal pieces that needs a large amount of pressing obviously needs the biggest press machines. At Ford Component Manufacturing the larger parts we make are primarily used for products used in the automotive, yellow & white goods and ventilation industries. However, our wide range of smaller sized press machines are used to make a multitude of more standard pressed parts.

We press many different types of materials, Stainless Steel, Carbon Steel, Aluminium and Copper, one of our more popular products are Washers, from the most common disc washer to the more specialised tab locking types used in the Aerospace, Defence and Rail Industries.

All our clients parts are made to their own individual specification, orders for standard pressed parts can range from “one-off’s”, to batch production. We are one of the top suppliers for more specialised products which are sold direct to market or through our sister company Ford Aerospace Ltd.

One of the most popular washer products in the Aerospace industry is the SP Series (SP41, SP42, SP43, SP44, SP45, SP46, SP107, SP108, SP109, SP110, SP111, SP112) SP washers are designed for use on large / slotted holes, painted / sensitive surfaces or soft materials. By using SP washers, the load is distributed over a larger surface area, and tend to be used on sensitive surfaces within the Aerospace Industry.

We can manufacture many other types of washer to most International specifications, our clients send us the details of their requirement for review, we provide a competitive quotation within 24 hours.

We are proud to be accredited to the industry standard ISO9001:2008 and are working towards being AS9100 REV C (also known as AS9100) and TS16949 approved in the near future.

Also available is documentation for PPAP, ISIR/FAIR, FMEA, APQP, CMM, SPC, with complete independent Chemical & Physical product testing.

Ford Component Manufacturing Pressing ahead to meet the demands in all industrial markets.