Related Products

Trunnion Assembly

This is an example of a Trunnion Assembly as manufactured by Ford Aerospace. The product was machined, treated, painted and assembled to the customer specification through a combination of in house process and specific supply chain management.

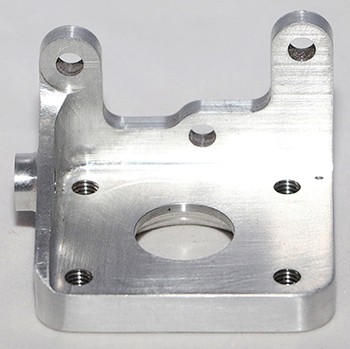

Bracket

This Bracket is an example of a complex part which we produce in house within the CNC milling section. It is manufactured on a five-axis machine in order to cut the number of operations, allowing the manufacturing time to be reduced, which reduces the lead time for the customer.

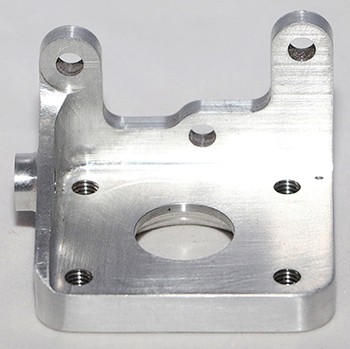

Housing

This housing is a component which Ford Aerospace will be producing in large quantities in the future. In order to make this feasible, we have developed a lean manufacturing process which combines and reduces the number of operations required, allowing a more efficient work flow from start to finish.

Spacer

Our spacers are produced within the CNC turning section, being manufactured complete in one operation due to the machining capabilities that we have. Starting with a raw billet, we machine the part down to the required size and profile before drilling the external holes, all from one setup.

Link

The Link is one of many vital parts we manufacture at Ford Aerospace. Being a vital part, the strict process from raw material purchase all the way to final dispatch is mutually agreed with the customer and followed exactly in accordance with their specifications. Ford’s capability is trusted by major OEMs to manufacture a range of flight-critical components.

Support Arm

This End Cap is produced in the CNC milling section and is manufactured in two operations. The milling of the outer profile and the inner features form one operation, followed by the backing off of the part to the correct thickness. This component also received treatments at a subcontractor, as per the customer’s requirements and is painted upon return.

Housing Bush

This housing bush was produced to the customer’s strict specification, which included dimensions with small tolerances, in order ensure that it would fulfil its purpose of joining two further components together. As the part would be visible when in use it was important to ensure that it was painted which would allow it to be aesthetically pleasing, but also to protect the item.

Forkend

This part is particularly complex to make, as it must be milled so that the fork is complete and then transferred to a lathe to allow the remaining bar to be turned down to size. It is thread rolled in order to produce a high quality thread and is then sent out to subcontractors for treatment processes.