Related Products

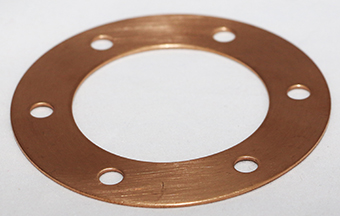

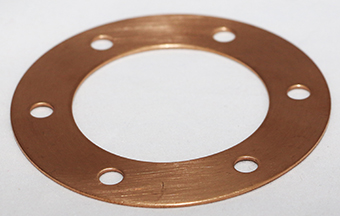

Side Gear Washer

This washer is manufactured from phosphor bronze at our High Volume cell; the part is produced in one hit on an automatically fed press and rumbled prior to shipping to our Customer.

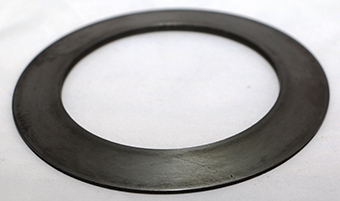

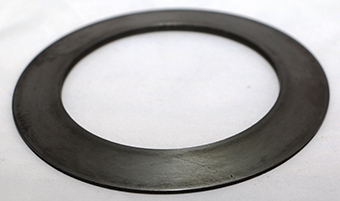

Spring Discs

Spring discs, because they are normally used in sets have several critical requirements such as height and hardness, this particular example is produced on our heavy presses, it is then sent for heat treatment and has a final rumbling opporation to remove any sharp edges and ensure the part is clean.

Metal Insert

Metal inserts are mainly produced at our high volume factory they are produced in one operation, and rumbled prior to dispatch.

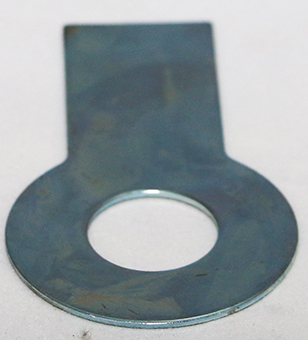

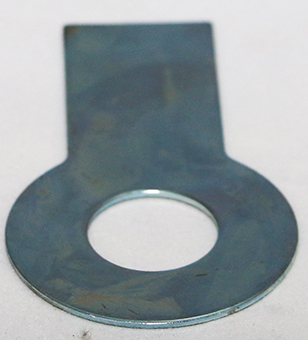

Tab Washer

This small standard type tab washer is pressed and formed complete at our High Volume factory then zinc plated and clear passivated.

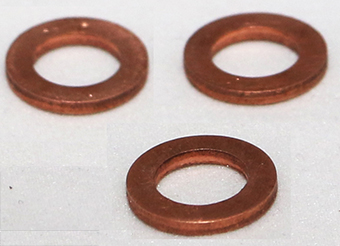

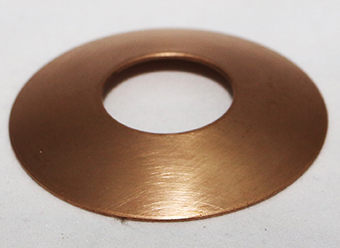

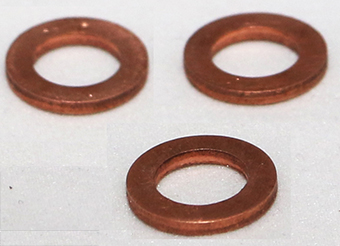

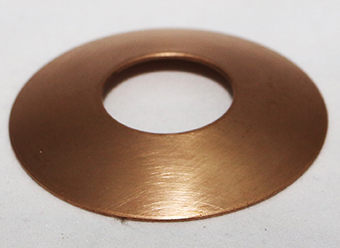

Copper Washer

Copper washers are made in large batches, these particular ones produced at our High Volume site are pressed and annealed on site before being despatched to the Customer.

Aluminium Fin

Aluminium fins are produced in a single operation, the fins are then dried (the oil used is evaporated) prior to inspection, packing and delivery.

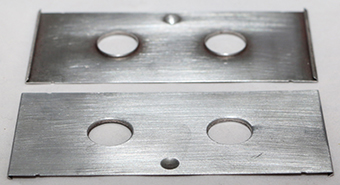

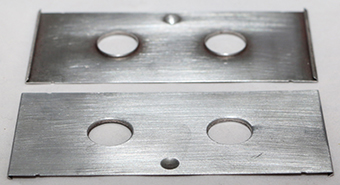

Standard Locking Plate

Standard Locking Plates can be produced several ways usually depending on quantity required, this example is pressed, then subcontracted to be zinc plated and passivated.

Fuse Cap

These copper zinc alloy fuse caps are produced in a single operation, they are then rumbled and inspected.

Spherical Washer

The phosphor bronze Spherical Washers are produced in one hit, dimples are added to the underside at the same time that the parts are pressed, the sharp edges are then removed and the parts inspected.

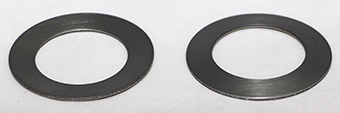

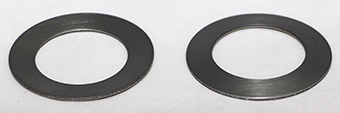

Belleville Washers

Belleville washers are manufactured at or North Shields site, they are pressed, then sent for sub contract heat treatment before being finally rumbled and inspected.

Hose Seal

Hose seals, although they have scalloped edges are produced by exactly the same method as plain edged seals, they are pressed in a single operation, inspected and packed.

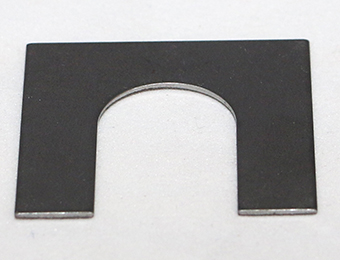

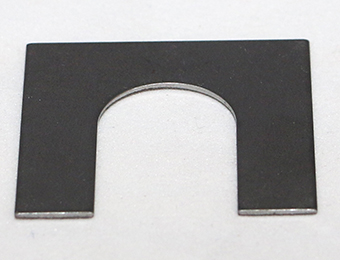

Shim

This type of shim can be produced by laser or press, this particular example is has a natural finish but often they are provided with a plated finish.

Oil Seal

Oil seals, also referred to as metal inserts, are pressed / formed at our North Shields site again in a single operation.